Popular Choice

Recommended For You

🔥 BEST SELLER

🌿 Compost Maker

₹ 149.00 Original price was: ₹ 149.00.₹ 100.00Current price is: ₹ 100.00.

🔥 BEST SELLER

🌿 Compost Maker

₹ 399.00 Original price was: ₹ 399.00.₹ 249.00Current price is: ₹ 249.00.

🔥 BEST SELLER

🌿 Compost Maker

₹ 3,500.00 Original price was: ₹ 3,500.00.₹ 2,649.00Current price is: ₹ 2,649.00.

🔥 BEST SELLER

🌿 Compost Maker

₹ 299.00 Original price was: ₹ 299.00.₹ 249.00Current price is: ₹ 249.00.

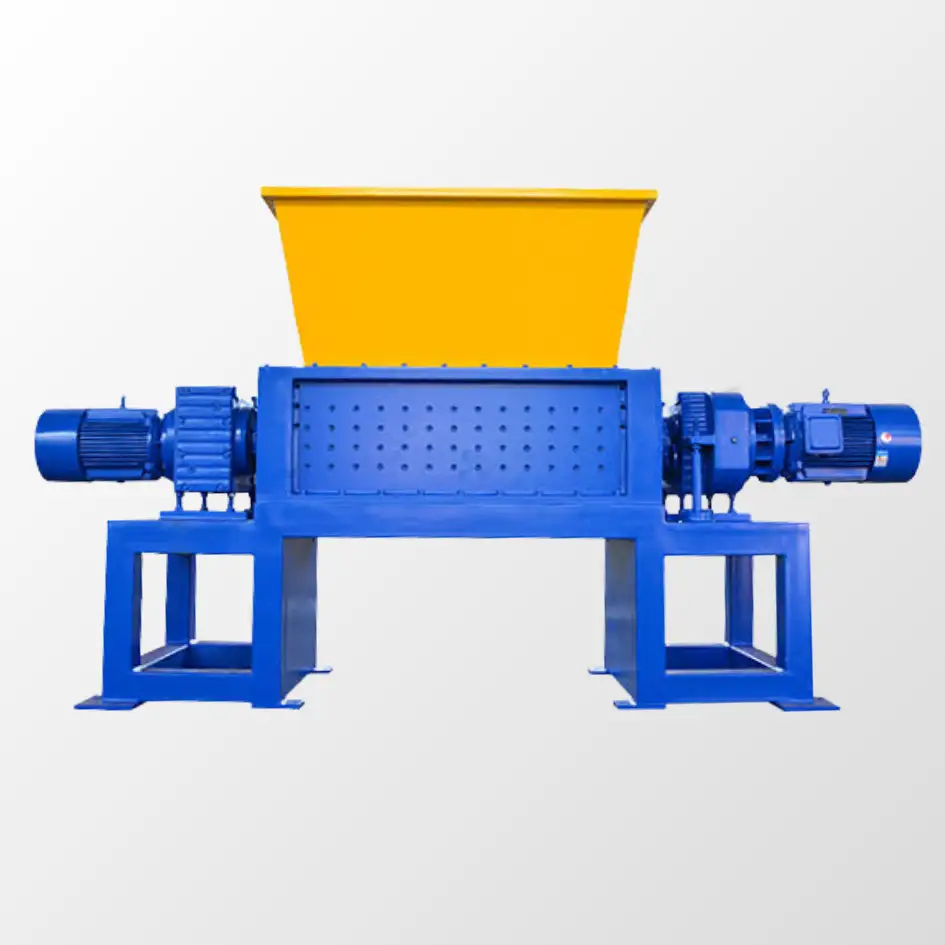

Plastic Waste Shredder Machine for Efficient Recycling and Waste Management

Store:

[dokan_store_link]

MRP:

(Inclusive of all taxes.)

YOUR OFFERS & GIFT CARDS 🏷️

Offers from brands for you! 🛒🛍️✨

[whatsapp_enquiry]

🌿 Features

- Heavy-Duty Blades: Capable of shredding various plastic types including PET, HDPE, and LDPE.

- High-Speed Operation: Fast processing to handle bulk plastic waste efficiently.

- Safety Mechanisms: Equipped with overload protection and emergency stop features.

- Energy Efficient: Designed to consume minimal power while maintaining high performance.

- Versatile Applications: Suitable for use in recycling plants, communities, and institutions.

📦 Available Capacities

- 5 HP – 250 kg/hr

- 7.5 HP – 400 kg/hr

- 10 HP – 500 kg/hr

- 15 HP – 750 kg/hr

- 20 HP – 1000 kg/hr

Share With

YOUR OFFERS & GIFT CARDS 🏷️

Offers from brands for you! 🛒🛍️✨

Modern recycling facilities increasingly depend on industrial-grade plastic waste shredders to process post-consumer and industrial plastics efficiently. According to the U.S. Environmental Protection Agency, proper size reduction through shredding can improve plastic recycling rates by up to 40%.

Why Plastic Waste Shredders Matter

These robust machines serve as the critical first step in the recycling chain by:

-

Reducing material volume by 70-80% (saving storage/transport costs)

-

Creating uniform flakes for easier washing and processing

-

Preparing materials for pelletizing or direct reuse

The Plastics Industry Association reports that properly shredded plastic has 30% higher market value than unprocessed waste.

Technical Specifications

Our plastic waste shredders feature:

✔ Dual-shaft design for tough materials

✔ 15-200 HP motor options

✔ Adjustable screen sizes (5-100mm output)

✔ Automated overload protection

✔ <75 dB noise operation

Common Applications:

• Municipal recycling programs (learn about our municipal solutions)

• PET bottle recycling plants

• Industrial plastic scrap recovery

• Post-consumer waste processing

Maximizing Your Investment

For optimal results, we recommend pairing your shredder with:

-

Plastic granulators for finer material preparation

-

Washing lines to remove contaminants

-

Optical sorters for material separation

A recent World Economic Forum study showed facilities using complete shredder-based systems achieve 90% material recovery rates versus 60% with manual processing.

Choosing the Right Model

Consider these factors:

-

Throughput needs (200-5,000 kg/hr options)

-

Material types (rigid/flexible blends require special cutters)

-

Space constraints (we offer vertical and horizontal configurations)

-

Future expansion (modular designs available)

Our engineers can help you select the perfect industrial shredder configuration for your specific needs.

Only logged in customers who have purchased this product may leave a review.

Vendor Information

- No ratings found yet!

-

Sale!

43%

43%Organic Panchakavya (1lit)

₹ 350.00Original price was: ₹ 350.00.₹ 200.00Current price is: ₹ 200.00. Add to Cart -

Sale!

25%

25%Greenrich CMS Soil Conditioner(500G)

₹ 400.00Original price was: ₹ 400.00.₹ 300.00Current price is: ₹ 300.00. Add to Cart -

Sale!

29%

29%Nutri Nourish Pellet 500g – Slow Release Fertilizer

₹ 350.00Original price was: ₹ 350.00.₹ 250.00Current price is: ₹ 250.00. Add to Cart -

Sale!

29%

29%Neem Fertilizer Pellets (500G)

₹ 350.00Original price was: ₹ 350.00.₹ 250.00Current price is: ₹ 250.00. Add to Cart -

Sale!

60%

60%BioBooster Concentrate 100ml

₹ 300.00Original price was: ₹ 300.00.₹ 120.00Current price is: ₹ 120.00. Add to Cart -

Sale!

48%

48%Fish Emulsion (100ml) – Organic Liquid Fertilizer

₹ 189.00Original price was: ₹ 189.00.₹ 99.00Current price is: ₹ 99.00. Add to Cart

- Login

- Sign Up

Greenrich Bazaar

Typically replies within minutes

Any questions related to Plastic Waste Shredder Machine for Efficient Recycling and Waste Management?

WhatsApp Us

🟢 Online | Privacy policy

Chat With us

YOUR OFFERS & GIFT CARDS 🏷️

Offers from brands for you! 🛒🛍️✨

Shop by Brands

Store

KMD FOODS

Reviews

There are no reviews yet